Leather Working at Szoneier: Precision, Craft, and Scalable Customization for Professional Brands

Leather working is both a science and an art. From precise material cutting to edge burnishing, from texture embossing to flawless stitching—every step in the process contributes to the final product’s quality, durability, and brand character.

At Szoneier Leather, we don’t just produce leather goods—we engineer and craft them with a depth of skill that comes from over 18 years of full-chain manufacturing experience. Our factory combines traditional craftsmanship with modern equipment to support everything from luxury-level detailing to scalable production for private label brands.

If You Can imagine it, We Will Create it!

Our team is here to help guide you through every step of the way. We help you imagine, design, and develop, your final product. We evaluate all details, ranging from materials, hardware, to embellishments, and more.

- OEM & ODM Available

Whether you are looking to launch your own leather products brand or wish to add to existing product line, our skilled craftsmen and scalable contract manufacturing facilities are ready to bring your vision to life.

- Free Design & Samples

Everyone deserves access to exceptional design, no matter their budget. That’s why we’re here,to provide quality design solutions that cater to your needs without compromising affordability.

- Start with No MOQ

For your first order, we support a MOQ of just 1 unit.Whether you’re testing the market, launching a new product line, or just exploring customization options, No MOQ ensures a hassle-free and cost-effective way to get started.

- Certified Quality

Compliant with OEKO-TEX®, GOTS,BSCI,SGS,ISO,Leather Working Group and other international standards, ensuring eco-friendly materials and ethical production processes.

Our Leather Working Principles

At Szoneier, leather working is not improvised—it’s engineered, tested, and optimized for both form and function. Our leather construction is built on three core principles:

- Structure First – Every edge fold, stitch seam, and hardware position is designed to reinforce durability and shape retention.

- Detail Obsession – We care about invisible seams, aligned grain patterns, and evenly cured edge paint as much as the final look.

- Brand Integrity – Whether you’re a heritage brand or a new label, we match your design language across product batches with absolute fidelity.

Suitable For:

- Luxury brands seeking premium finishing

- Small-batch custom buyers needing flexibility

- Large-scale programs needing stability and consistency

Szoneier Core Leather Working Capabilities

We specialize in precision leather craftsmanship—offering expert cutting, stitching, edge painting, embossing, and logo application. Our in-house artisans and advanced equipment ensure every product meets the highest standards of detail, durability, and consistency. Perfect for brands seeking refined quality and scalable production.

1. Precision Cutting & Material Preparation

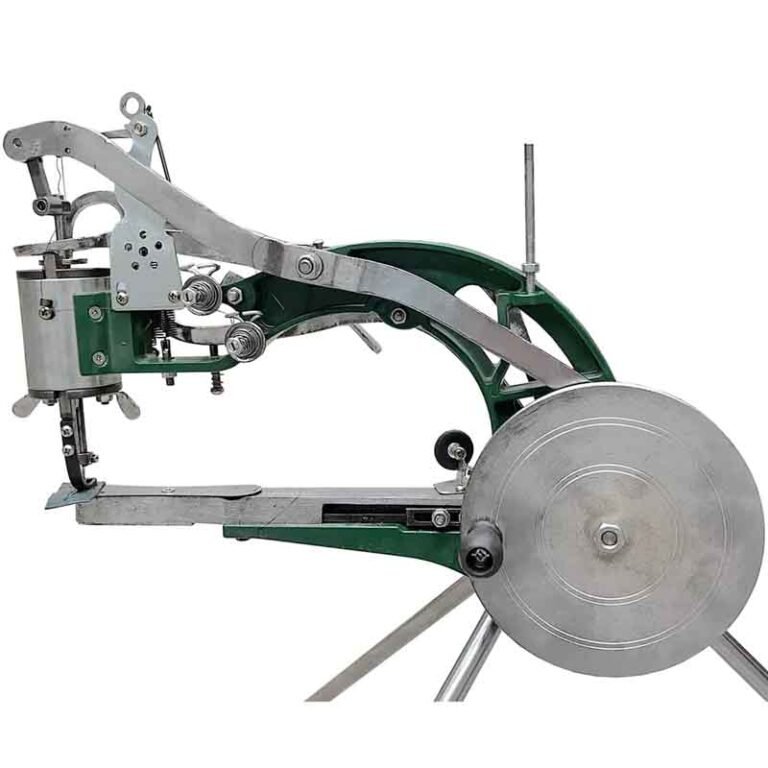

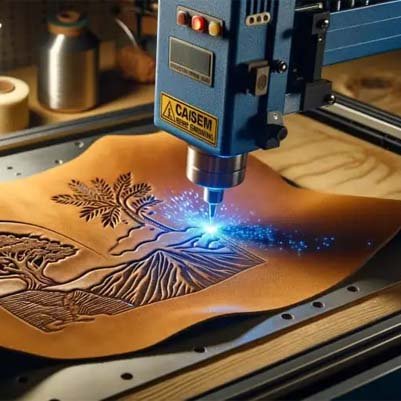

- Full support for hand-cut patterns, die-cut molds, CNC plotters, and rotary blade machines

- Leather thickness trimmed with ±0.1mm tolerance for consistency across layers

- Texture direction and grain alignment checked pre-assembly

- All prep done in a dust-free, temperature-stable environment

2. Edge Finishing & Sealing

- Multiple layers of Italian-imported edge paint (Giardini or Fenice) for smooth, durable edges

- Edge sealing includes burnishing, sanding, heat sealing, and waxing, depending on leather type

- Multi-color edge styling available for fashion and limited edition products

3. Stitching Systems (Manual + Automated)

- Saddle stitching (hand-stitched) for high-end items, using waxed thread

- Flat-bed and post-bed machines for industrial stitching with precision control

- Stitch spacing controlled at 3mm / 4mm / 5mm by application type (e.g. card slot vs bag panel)

- Reinforcement stitching for stress points using X-box or bar-tack stitching

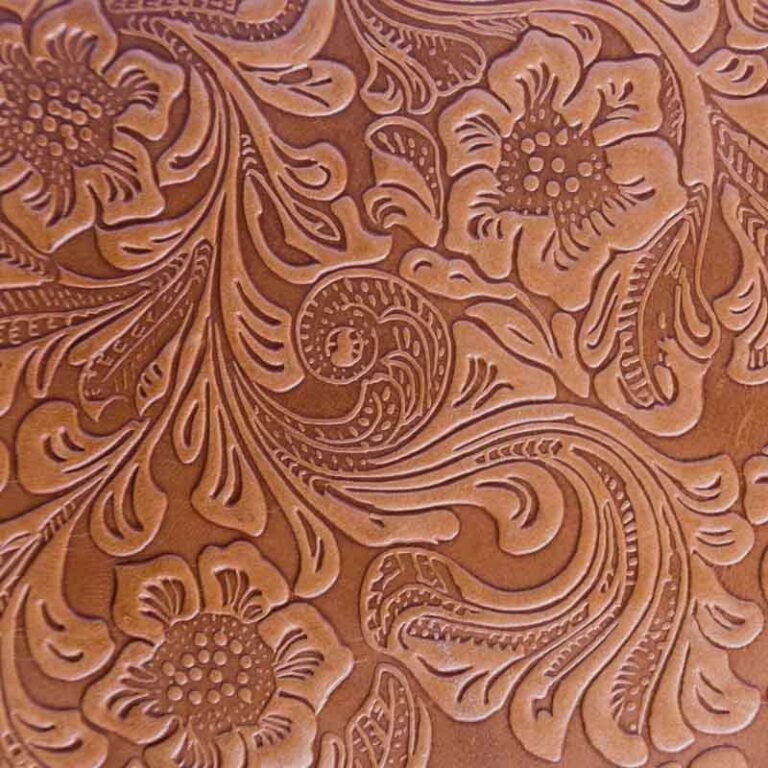

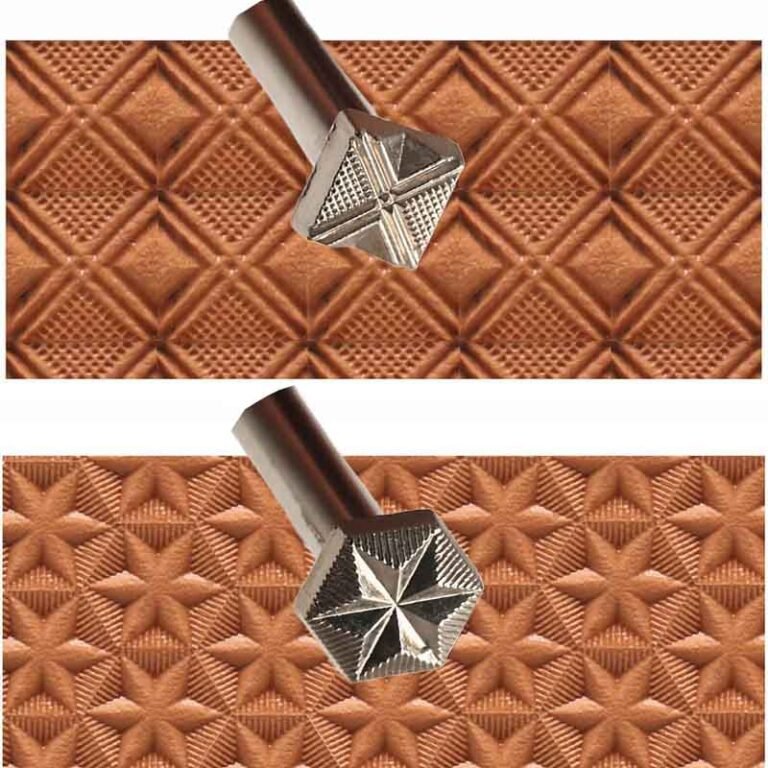

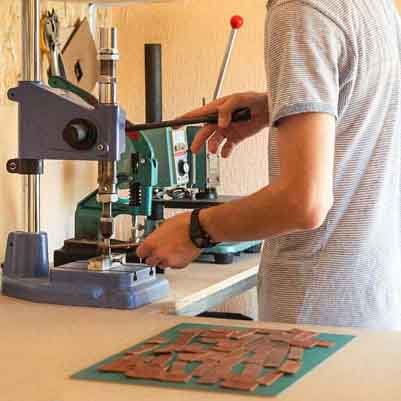

4. Embossing, Debossing & Branding Textures

- Blind embossing, hot foil stamping, or deep debossing options

- Custom embossing rollers for repeating texture patterns (e.g. logo monogram, crocodile)

- Accurate positioning using laser alignment jigs

- Surface temperature, pressure, and dwell time precisely controlled

5. Structural Assembly & Lining Integration

- Multi-layer leather lamination for wallets, folios, and organizers

- Lining includes PU-backed microfiber, cotton twill, polyester silk, suede

- Optional intermediate reinforcement layers (paperboard, fiberboard, foam core) for rigidity

- Edge folding or top-stitching per customer design

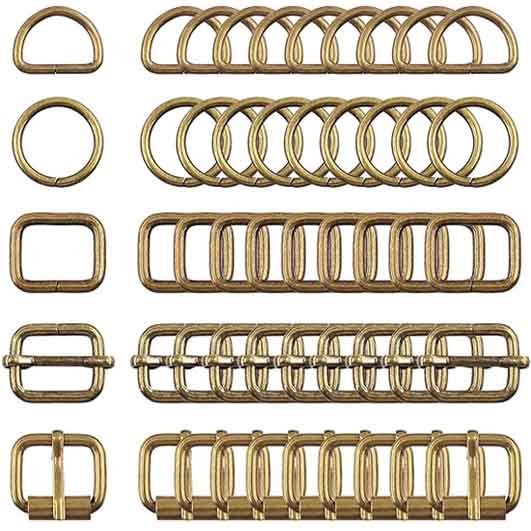

6. Hardware Installation

- Snap buttons, magnetic clasps, belt buckles, zippers, rivets—installed with industrial-grade presses

- Pull tension, rotation clearance, and torque strength all tested pre-shipment

- Metal fixtures available in brushed, matte, chrome, antique brass finishes

Process Standardization for Brands

At Szoneier, leather working is not improvised—it’s engineered, tested, and optimized for both form and function. Our leather construction is built on three core principles:

- We provide product technical sheets and cutting templates for each approved sample

- Each stitching thread, edge color, and pattern direction is documented

- Our production line includes first-piece QC, midline inspection, and final QA station with photo reference matching

- For large brands: we assign a dedicated process manager to supervise repeat orders

Leather Working by Product Type

From structured handbags to slim wallets, durable belts, luxury boxes, and functional straps, we tailor our leather working techniques to match each product’s unique construction needs. Every stitch, edge, and finish is adapted to the form and function of your item—ensuring lasting quality and premium appearance across all categories.

Bags & Totes

- Structural reinforcement on base and handle area

- Full edge piping or hidden seam construction

- Custom zipper pull designs and inner pocket lamination

Wallets & Card Holders

- Ultra-precise alignment of multi-slot interiors

- Anti-warp lamination and colorfast linings

- Optional RFID shielding layer insertion

Belts & Straps

- Single-layer or double-ply core bonding

- Custom punch patterns and buckle slot machining

- Waxed edges or burnished edge options for longevity

Boxes & Accessories

- 90° fold wrapping with tension-control gluing

- Flush-fitting magnetic lid closures

- Sharp corner finishing or rounded soft edge sculpting

leather materials

working Tools

Leather Hardware

Machinery

Why Szoneier Leather for Professional Leather Working?

With over 18 years of experience in leather craftsmanship and full-scale manufacturing, Szoneier Leather stands as a trusted partner for brands and custom buyers worldwide. Here’s why clients choose us for professional leather working:

1. Full In-House Leather Production

All core processes—from material cutting to edge painting and stitching—are handled in-house under strict quality control. This ensures speed, precision, and accountability at every step of your project.

2. Expert in Diverse Leather Materials

We work with a wide range of materials including:

- Full-grain, top-grain, and split leather

- PU leather, microfiber leather

- Suede, nubuck, vintage oil-waxed hides

- Vegan plant-based leather (e.g. cactus, apple)

Each type is treated with the correct working technique to preserve structure, texture, and finish.

3. Precision Meets Craftsmanship

Our skilled artisans and industrial-grade machines work hand-in-hand:

- CNC cutting machines for accurate patterns

- Programmable stitching units for ±0.5mm stitch control

- Multi-layer Italian edge painting and burnishing

- Blind embossing, foil stamping, and custom logo applications

Even high-volume orders retain fine detailing.

4. Customization Without Limits

We support complex product builds:

- Hand-stitching for premium lines

- RFID-protected wallet construction

- Metal logo plate installation

- Custom die-cut linings, straps, buckles, and closures

Your designs are fully brought to life without compromise.

5. Low MOQ & Brand-Friendly Support

We work with both growing and established brands.

- Low minimums (starting from 100pcs)

- Free sampling & prototyping guidance

- One-on-one development support from concept to mass production

6. Proven Export Experience & Quality Assurance

We’ve served clients across the US, Europe, Middle East, and Australia.

- All batches pass pre-shipment QC

- Golden sample verification

- Optional third-party testing (REACH, RoHS, FSC, etc.)

Cooperating Brands Trusted

Your product is produced in reliable leather factory like our already cooperating international brand partners below:

Effective Production Process

We believe quality is always the key to success, which includes a responsible approach to manufacturing, and controlling whole process.

Q1. Can we use our own stitch spacing or custom construction method?

Yes. Our engineers will follow your tech pack or provide structural CAD feedback for reinforcement improvements if needed.

Q2. How do you ensure consistency in edge paint quality across thousands of pieces?

We use automated paint machines with IR drying systems and multi-round inspection across batches.

Q3. Do you accept partial handcrafting mixed with industrial production?

Absolutely. Many clients use hand-stitched detailing combined with machine-stitched body construction for cost-performance balance.

Q4. Can I request video proof of production or quality control?

Yes. For larger clients or high-value orders, we offer real-time production updates via video or internal QA report delivery.

Q5: Is leatherworking hard to learn? A: Leatherworking is easy to start with and has a steep learning curve for more advanced techniques. The key is practice and learning from mistakes.

Q6: What are good beginner projects for leatherworking? A: A simple wallet, keychain, or dog collar is a great way to start, teaching basic skills such as cutting, dyeing, stitching, and burnishing.

Q7: How do I maintain my leather creations? A: Regularly condition leather to keep it supple and prevent cracking. Store leather items in a cool, dry place away from direct sunlight.

Frequently Asked Questions

Welcome to the FAQs on branded personalized leather products in bulk, where we address your common questions and provide insights on styles, features,and related matters, ensuring you make informed choices for your business.

how to guide to learning leather crafting:A ultimate guide

Leatherworking is a craft that allows you to transform raw leather into beautiful, functional items. Whether you’re creating wallets, belts, bags, or intricate artwork, the art of leather crafting combines creativity, technique, and patience. This guide will walk you through everything you need to know about leatherworking, from essential tools to advanced techniques, helping you master the art of turning leather into long-lasting, high-quality products.

1. What Is Leatherworking?

Leatherworking, also known as leather crafting, involves creating products by manipulating leather through processes such as cutting, molding, dyeing, tooling, and stitching. Leatherworkers can make a wide range of objects—from practical items like bags, belts, and wallets to decorative pieces like art and sculptures.

Key Processes in Leatherworking:

- Cutting & Shaping: The leather is carefully cut to the desired shape and size, whether by hand or with specialized tools.

- Carving & Stamping: Using carving tools and stamps, designs or patterns are etched or pressed into the leather surface, creating texture and visual appeal.

- Dyeing & Finishing: Leather can be dyed in a variety of colors, from deep browns and blacks to vibrant hues, and finished to protect and enhance its longevity.

- Sewing & Assembly: Leather pieces are stitched together using specialized needles and thread, with care taken to ensure strength and durability.

Whether you’re making practical objects like footwear, bags, or upholstery or artistic leather goods, leatherworking allows you to express creativity while producing functional, quality items.

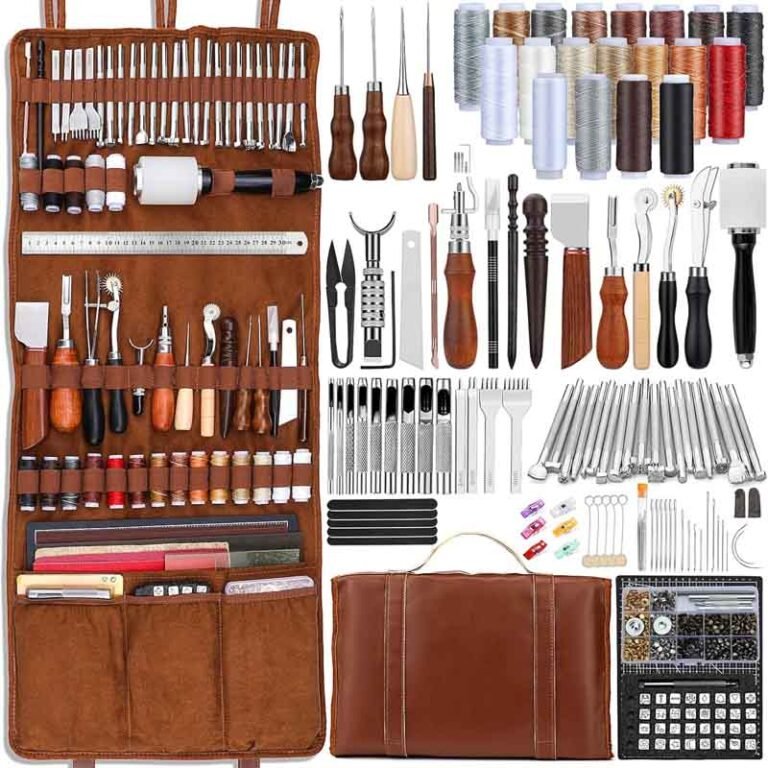

2. Essential Leatherworking Tools

Before you dive into your first leatherworking project, it’s essential to familiarize yourself with the basic tools of the trade. Fortunately, leatherworking requires relatively low startup costs and tools that are versatile enough to last through a variety of projects.

Common Leatherworking Tools

| Tool | Purpose |

|---|---|

| Awl | Used for marking, piercing, or sewing leather to create precise holes or guide stitching. |

| Beveler | Removes sharp corners, rounding edges to create a polished finish. |

| Burnisher | Smooths and seals the edges of leather, often made from wood or bone. It is used by applying friction to make the edges shine and become hardened. |

| Cutting Tools | Different types of cutters, such as rotary cutters, utility knives, and strap cutters, to cut leather for various shapes. |

| Leather Glue | Specialized adhesive designed to bond leather pieces together before stitching. |

| Maul (Leather Mallet) | A striking tool used for stamping, tooling, or setting rivets without damaging the leather surface. |

| Pricking Iron & Chisel | These tools are used to mark holes for stitching, helping create even, precise stitch holes in leather. |

| Punch | Creates holes for rivets, snaps, or any fasteners needed in a leather project. |

| Skiver | A tool used to shave or thin the leather to reduce its thickness for making folds or seams. |

| Stamps & Carving Tools | Used to decorate the leather with different textures and designs. |

| Sewing Tools | Needles, waxed thread, and stitching tools such as a stitching pony (which holds leather while stitching). |

| Cutting Mat | Protects your work surface from damage when cutting leather with a blade. |

Each of these tools is relatively affordable and serves an essential function in leatherworking. If you’re just starting out, it’s best to invest in basic tools and slowly build up your collection as your skills develop.

3. Understanding and Sourcing Leather

Leather is made from animal hides, usually from cows, pigs, or goats. The choice of leather greatly impacts the final product, so understanding the types of leather available is crucial. The two most common types used in leather crafting are vegetable-tanned and chrome-tanned leather, which differ in the way they are processed and their resulting characteristics.

Types of Leather

Vegetable-Tanned Leather (Veg-Tan)

- Tanning Process: Veg-tan leather is tanned using tannins derived from plant materials, like tree bark, and is an all-natural process.

- Characteristics: It’s thicker, stiffer, and takes longer to produce. It also darkens naturally over time, developing a beautiful patina.

- Uses: Best for projects that require durability and strength, such as saddles, belts, and wallets.

Chrome-Tanned Leather

- Tanning Process: This type of leather is tanned with chromium salts in a quicker process that results in a softer and more supple leather.

- Characteristics: It’s thinner, more flexible, and faster to produce but is less durable than veg-tanned leather.

- Uses: Ideal for projects that need to be flexible or colorful, such as bags, clothing, or upholstery.

Suede & Nubuck

- Suede: Soft, velvety texture created by sanding the inner surface of the leather.

- Nubuck: Similar to suede, but it’s made from the outer surface, giving it a finer, smoother finish.

Where to Source Leather

- Local Leather Suppliers: For high-quality, locally sourced leather, check with leather-specific suppliers or craft stores.

- Specialty Retailers: Companies like Tandy Leather and other online retailers offer leather hides in various thicknesses and finishes, ideal for beginners.

- Tanning Companies: If you want to work with custom leather or more specialized leathers, you can contact tanneries directly to order hides in bulk or unique finishes.

4. Cutting and Preparing Leather

Once you’ve sourced your leather, it’s time to prepare it for your project. Proper preparation and cutting techniques will ensure your project comes out perfectly.

Inspecting Leather

Before cutting, inspect your leather hide for any natural blemishes, scars, or defects. You want to choose the cleanest section of the hide for your project to avoid compromising the aesthetic or structure of your final product.

Cutting Leather

Cutting leather requires precision to ensure clean lines and smooth edges.

- Scissors/Shears: Good for cutting smaller pieces of thinner leather.

- Utility Knife/Rotary Cutter: Useful for cutting both straight lines and curves in thicker leather, but it requires a steady hand and a sharp blade.

- Strap Cutter: Ideal for cutting consistent strips of leather for handles, belts, or straps.

- Cutting Mat: Always use a cutting mat to protect your work surface and maintain sharpness in your blades.

Patterning and Marking

To avoid errors when cutting, use a paper pattern or templates. Mark your cutting lines with a pencil or chalk that can be easily erased later.

5. Leatherworking Skills and Techniques

With your leather cut and prepped, it’s time to get into the fun part: crafting! Here are some essential leatherworking skills you will need to master to create beautiful, durable leather pieces.

Gluing Leather

Gluing leather is the easiest way to join pieces before stitching. Here’s a simple process:

- Surface Prep: Make sure both surfaces are clean. You can lightly sand or roughen slick surfaces for better adhesion.

- Apply Glue: Use a thin, even layer of leather glue.

- Press Together: Once the glue is applied, press the pieces together and let it dry for several hours. Avoid disturbing the pieces while the glue bonds.

Saddle Stitching

Saddle stitching is the most durable hand-sewn stitch used in leatherworking. It involves two needles, each with a thread passing through the leather. This method results in a strong, locked stitch. It’s ideal for items like wallets, belts, and bags.

- Mark Holes: Use a pricking iron to make evenly spaced holes.

- Thread Needles: Attach a length of waxed thread to each needle.

- Sew: Pass one needle from one side and then the other, locking the thread after each pass.

Dyeing Leather

Dyeing leather adds color and depth. It works best on vegetable-tanned leather. Here’s how to do it:

- Choose Your Dye: Leather dyes come in various forms: spirit-based, water-based, and acetone-based. Spirit dyes offer deeper penetration, while water-based dyes are perfect for surface color.

- Application: Apply with a sponge or dauber, using multiple thin layers for even coverage. Allow each layer to dry before applying another.

- Finishing: After dyeing, seal the leather with a topcoat for protection.

Burnishing Leather Edges

Burnishing gives the edges of your leather a smooth, glossy finish. It also seals the edges to prevent fraying.

- Beveling: Use a beveler tool to round the edges.

- Burnishing: Use a burnisher to rub the edges with friction, applying pressure to smooth and polish.

Skiving Leather

Skiving is the process of shaving off layers of leather to reduce its thickness, making it more flexible for folds or seams.

- Use a Skiver Tool: A metal skiver removes thin layers from the surface of the leather.

- Smooth the Surface: Use a smoothing tool or burnisher to keep the surface even and neat.

6. What Can You Make with Leather?

Leatherworking is incredibly versatile. Once you’ve mastered the basics, the sky’s the limit. Some great beginner projects include:

- Keychains

- Wallets

- Phone Sleeves

- Dog Collars

- Belts

- Small Pouches or Bags

As you progress, you can challenge yourself with more complex items such as:

- Handbags

- Shoes or Moccasins

- Saddles or Seats

- Furniture Upholstery

- Football or Soccer Ball Covers

Each project allows you to refine your skills and add new techniques to your repertoire.

7. How to Learn Leather Crafting: Resources & Next Steps

- Local Workshops & Classes: Many craft centers offer hands-on classes for leatherworking beginners. These classes will teach you essential techniques and help you get comfortable with the tools.

- Online Learning: There are many online tutorials and video classes that can teach you basic and advanced techniques. Websites like Skillshare, YouTube, and Udemy offer step-by-step guidance.

- Books & Resources:

- The Leatherworking Handbook by Valerie Michael

- The Art of Hand Sewing Leather by Al Stohlman

Tip: Don’t rush! Leatherworking requires patience, but each project will teach you something new. Start with simple projects and gradually challenge yourself as your skills grow.

Leatherworking is a rewarding and flexible craft. With the right tools, materials, and patience, you can create both practical and beautiful pieces that will last for years. Start small, practice regularly, and soon you’ll be able to craft professional-quality leather goods! Happy crafting!

Turn Your Leather Design into a Product That Performs

Whether you’re a brand looking to develop signature leather goods, a buyer sourcing factory-level finishing, or a designer needing technical execution—Szoneier is your solution.